Unlocking Precision: The Screw Gauge’s Secret to Perfect Measurements Revealed

Introduction

n the field of precision measuring instruments, the screw gauge stands as an indispensable tool for engineers, machinists and scientists. Also known as a micrometer screw gauge, this instrument allows highly accurate measurement of small distances with a level of precision that is important in a variety of industries. In this article, we explore the intricacies of the screw gauge, its components, workings, and the mathematical formulas that govern its accuracy.

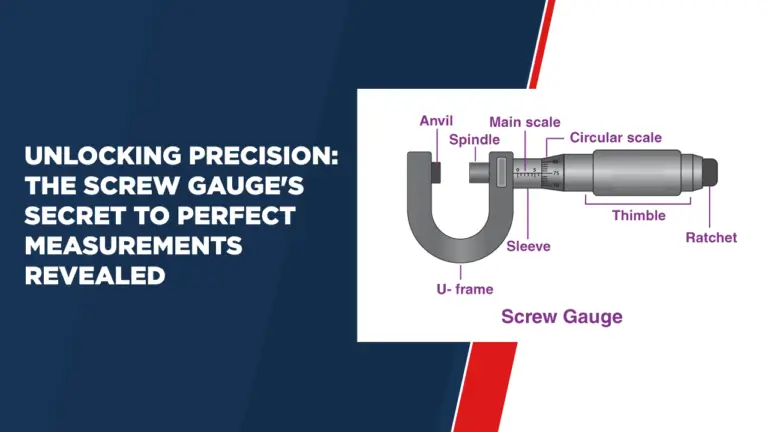

Components and Diagram

[Diagram Image]

A typical screw gauge consists of a U-shaped frame, a thimble, and an anvil. The U-shaped frame holds the anvil at one end and the thimble at the other, providing structure for the tool. The thimble is rotated to move the anvil closer to or away from the spindle, which holds the object being measured. The spindle itself has a precision-ground screw thread. The screw gauge diagram shows the arrangement highlighting the major components that contribute to its functionality.

Pitch and Least Count

The pitch of the screw gauge refers to the distance traveled by the spindle in one complete rotation of the thimble. This is an important factor in determining the measurement sensitivity of the instrument. The pitch of a screw gauge is inversely proportional to its minimum count – the smallest measurement between which it can distinguish. The formula to calculate the minimum count of screw gauge is given as:

Least Count = Pitch / Number of divisions on the circular scale

This formula underscores that finer divisions on the circular scale result in a smaller least count, enabling more precise measurements.

Screw Gauge Formula

The screw gauge formula enables users to accurately calculate measurements based on the rotational movement of the thimble and the associated displacement of the spindle. The formula is:

Measurement = Pitch × Number of rotations of the thimble + (Pitch / Number of divisions on the circular scale) × Reading on the circular scale

This formula takes into account both the coarse movement due to the rotation of the thimble and the finer adjustment enabled by the circular scale.

Screw Pitch Gauge

Different items require different levels of accuracy, which is where a screw pitch gauge comes in handy. Screw pitch gauges are used to measure the pitch of screw threads on nuts and bolts. It provides a quick and accurate method for determining the number of threads per unit distance, aiding in quality control and engineering applications.

Conclusion

The screw gauge, with its precision-engineered components, precise design and mathematical formulas, exemplifies the marriage of science and practicality in measuring instruments. Its ability to provide accurate measurements down to a fraction of a millimeter has made it an essential tool in countless industries. By understanding its components, pitch and minimum count, users can harness the full potential of a screw gauge to achieve the highest level of measurement accuracy in their work. Whether it is the manufacture of mechanical components or the analysis of microstructures, screw gauges remain a symbol of precision in the modern world.